SAW filter design optimization

Accelerating SAW filter design via parallel frequency & geometric sweeps

Electrostatics • Solid mechanics • Elastic waves • Electromechanics

The challenge

Surface Acoustic Wave (SAW) filters are critical for 5G/6G signal integrity but are notoriously sensitive to geometric deviations.

Optimizing them requires analyzing hundreds of frequency points to determine resonance and bandwidth. Sequential simulation of these frequency sweeps on local hardware takes hours, creating a major bottleneck in the design cycle.

Approach with Quanscient Allsolve

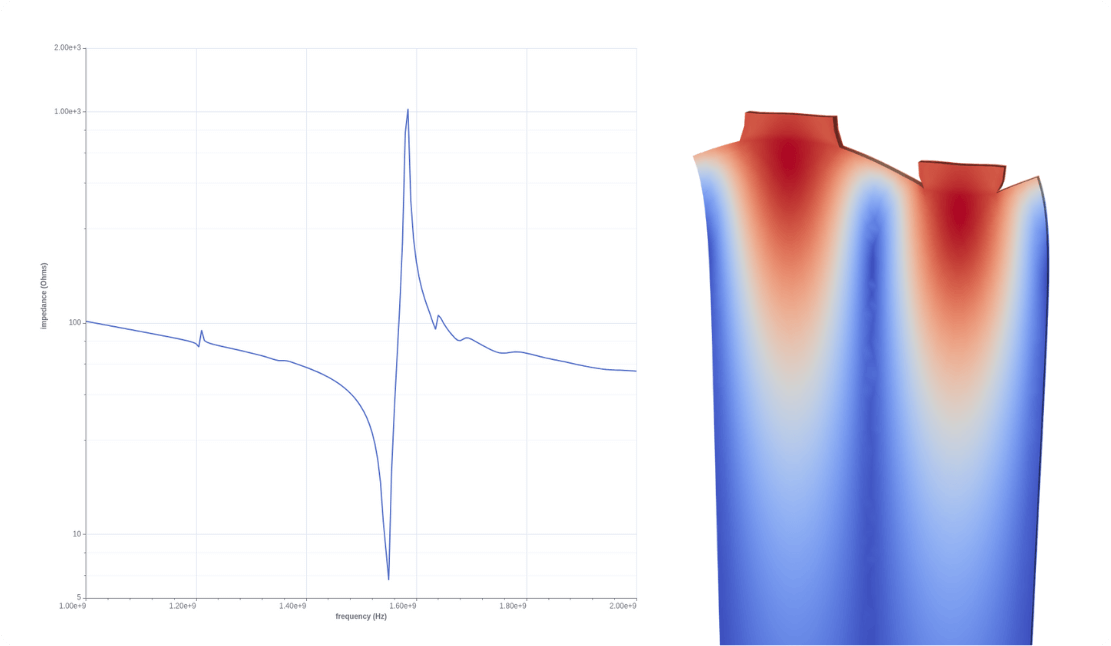

The study utilized Quanscient Allsolve’s cloud parallelism to run a 200-point frequency sweep of a single-cell periodic SAW structure.

The platform simultaneously solved 50 frequency points at a time, rather than one after another. It also performed full 3D transient simulations (3.8M DoF) to analyze edge leakage and wave propagation in the time domain.

Key results

- Time reduction: The 200-point frequency sweep completed in 90 seconds (parallel) compared to 73 minutes (sequential).

- High fidelity: Handled a 3.8 Million DoF model for full 3D transient analysis in just 218 seconds (2.4 core-hours).

- Multiphysics accuracy: Fully coupled Piezoelectric-Electrostatic-Elastic solvers accurately predicted resonance modes and passband characteristics.