PMUT sensor yield prediction

Predicting fabrication yield of PMUT sensors via Monte Carlo analysis

Electrostatics • Solid mechanics • Acoustic waves • Acoustic-Structure Interaction

The challenge

PMUT fingerprint sensors are highly sensitive to microscopic fabrication tolerances (e.g., layer thickness variations). Deterministic simulations cannot predict real-world manufacturing yield.

To ensure reliability, engineers need to simulate thousands of geometric variations (Monte Carlo analysis), which traditionally requires days of sequential computing time.

Approach with Quanscient Allsolve

The study utilized Quanscient Allsolve’s cloud-native parallelization to run a Monte Carlo sweep of 1,000 randomized designs simultaneously.

The simulation involved strongly coupled multiphysics (Piezoelectric-Acoustic-Structure interaction) to capture the complex signal amplitude and arrival times for every single geometric variation.

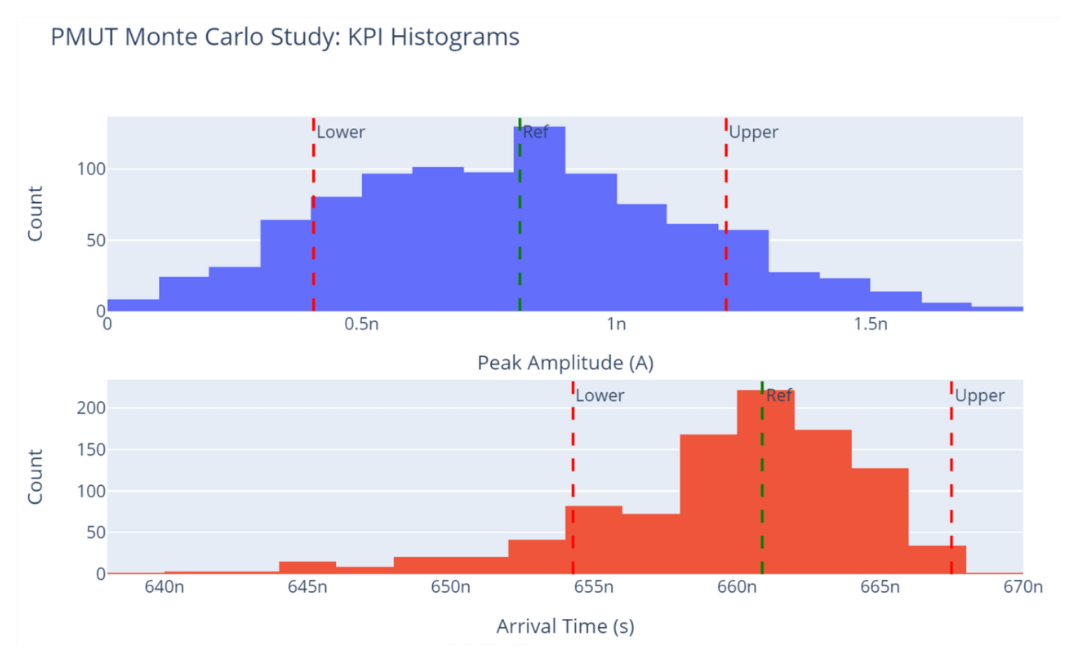

Key results

- 260x speedup: Completed 1,000 complex transient simulations in 15 minutes (cloud parallel) compared to 66 hours (sequential).

- Yield estimation: Predicted a manufacturing yield of 71.9% based on strict pass/fail criteria for signal integrity.

- Sensitivity analysis: Revealed that oxide layer thickness was the primary factor driving variations in signal arrival time.