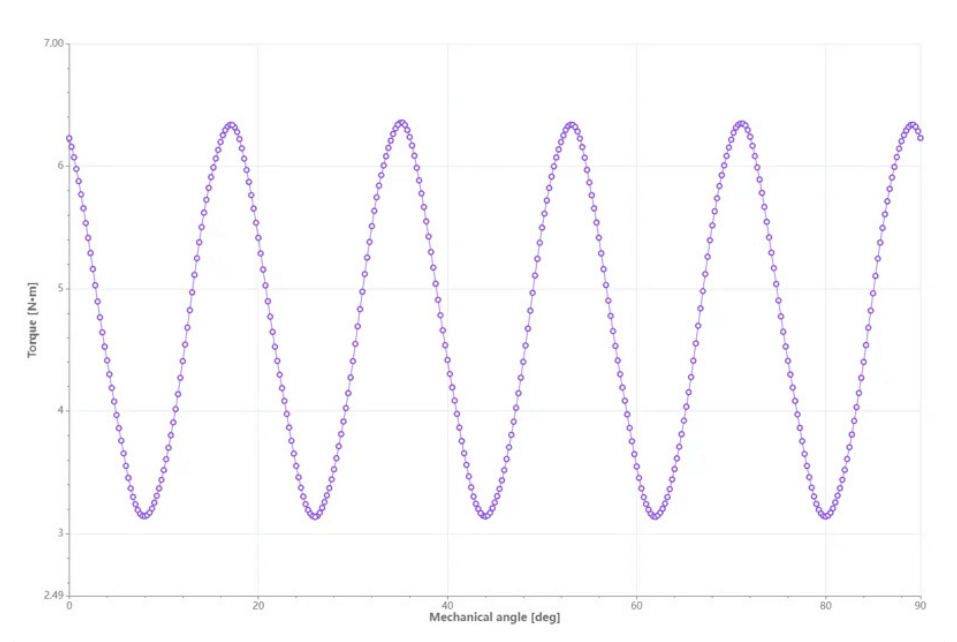

PMSM torque ripple analysis

Accelerating PMSM torque ripple analysis via cloud-native parallel sweeps

.png?width=300&name=em-visualization%20(1).png)

Magnetism A • Current flow • Solid mechanics • Electromechanics

The challenge

Permanent Magnet Synchronous Motors (PMSMs) require precise optimization of rotor and stator geometry to minimize torque ripple—a primary cause of noise and vibration in EVs.

Simulating a full 3D torque rotation curve is traditionally a bottleneck because it requires solving Maxwell’s equations sequentially for dozens of discrete rotor angles, which takes hours or days on local hardware.

Approach with Quanscient Allsolve

The study utilized Quanscient Allsolve’s cloud-native parallelization to perform a granular parametric sweep of the rotor angle over a 90° segment.

Instead of simplifying the geometry, the team imported the complex CAD (12 coils, 10 magnets) directly without cleanup and distributed the solver workload across the cloud to handle the massive computational load of high-fidelity 3D fields.

Key results

- Massive time savings: By running all 361 rotor angle steps simultaneously (in parallel) rather than one-by-one, the total time to solution was reduced from hours to minutes.

- High fidelity: Captured critical torque ripple oscillations and magnetic saturation effects without compromising mesh density.

- Workflow efficiency: Direct CAD import removed the manual geometry preparation typically required for 3D motor models.