Key takeaways

-

Physical prototyping limits the speed and flexibility of PMSM development.

-

Traditional simulation tools are slow and require significant computing resources.

-

Quanscient Allsolve enables fast, high-fidelity simulations through cloud-native computing.

-

Parallel processing allows efficient torque ripple analysis across multiple rotor positions.

-

Engineers gain faster insights and can explore more design options with greater accuracy.

Introduction to Permanent Magnet Synchronous Motors (PMSMs)

PMSMs are central to many modern technologies. From electric vehicles to elevators and high-performance industrial machines, PMSMs provide the torque and control needed for efficient, reliable motion. As demand for these applications grows, so does the need for better motor performance, along with shorter development cycles and reduced costs.

Traditionally, developing new PMSM designs has relied heavily on physical prototyping. Engineers build, test, and refine physical versions of a motor before finalizing a design. While this process ensures reliability, it’s slow, expensive, and limits the number of iterations that can realistically be explored.

Simulation offers an alternative. By simulating a motor’s behavior virtually, engineers can try out multiple design iterations without physically building them. This accelerates development, reduces material waste, and allows for deeper design exploration. But PMSM simulations, especially detailed 3D models, can be computationally demanding. Without the right tools, engineers face a new challenge: long simulation times and complex modeling workflows.

This is where Quanscient Allsolve comes in. By combining advanced multiphysics capabilities with cloud-native computing and automation, Quanscient Allsolve makes it easier and faster to simulate electric motors, even for engineers working on standard laptops.

In this blog, we’ll explore how Quanscient Allsolve improves the PMSM simulation process, with a focus on one specific use case, obtaining the torque vs mechanical angle curve, including an analysis of torque ripple.

Why simulate PMSMs?

PMSMs are known for their high efficiency, torque density, and excellent dynamic performance. These qualities make them ideal for demanding applications, such as:

- Electric vehicles (EVs) where efficiency and precise torque control are essential for performance and range.

- Elevators and robotics where reliability and smooth operation are critical.

- Industrial machinery where dynamic response and efficiency impact productivity.

However, these same applications also impose tight performance and design constraints. Engineers must optimize every detail—from the geometry of the rotor and stator to the material properties and winding patterns. Each decision can affect efficiency, torque ripple, heat generation, and cost.

Simulating PMSMs allows engineers to evaluate performance without the delays and expenses of physical testing. A well-set-up simulation can answer critical questions:

- What is the torque at different rotor positions?

- How large is the torque ripple?

- How will the motor behave under different loading conditions?

- Are there any hotspots or magnetic saturations?

Answering these questions early allows for faster iteration, better designs, and fewer surprises in later development stages.

Challenges with simulating PMSMs

While the benefits are clear, PMSM simulation comes with its own challenges.

First, the simulations are complex. They involve solving Maxwell’s equations to determine electromagnetic behavior, which can include hundreds of thousands or even millions of unknowns, especially in high-resolution 3D models.

Second, the simulations are computationally heavy. Even simple static simulations may take hours to complete using traditional software tools on local hardware. Time-dependent simulations are even more demanding.

Third, simulations are often iterative. One simulation rarely provides all the needed insight. Engineers must test multiple geometries, sweep through different angles or loads, and evaluate many configurations. Each variation adds to the total compute time.

These factors often lead to bottlenecks. Engineers either have to compromise on model fidelity to get results faster or spend long hours waiting for results.

Quanscient Allsolve’s benefits on PMSM simulations

Quanscient Allsolve is a cloud-native multiphysics simulation platform. It brings together physics solvers, geometry processing, and advanced computing to support faster, more efficient design workflows. In the context of PMSM simulations, Allsolve introduces several key advantages:

CAD-Friendly Simulation Workflow

Many simulation tools require reworking or simplifying CAD files before simulation, especially when dealing with complex motor geometries. Quanscient Allsolve eliminates this bottleneck.

The platform supports a wide range of native CAD formats, so engineers can import models directly from CAD software. No need for manual rework, meshing corrections, or geometry cleaning. This streamlines the setup process and reduces preparation time dramatically.

Cloud-Native Computing

Quanscient Allsolve runs on the cloud, making high-performance computing accessible to everyone. Simulations that would traditionally require expensive on-premises clusters can now run efficiently from any standard PC or laptop.

This is particularly useful for PMSM simulations. Electromagnetic field simulations, especially in 3D, quickly grow in size and complexity. With Allsolve’s parallel processing capabilities, large models can be solved significantly faster.

Even for simulations with hundreds of thousands of unknowns, results can be obtained in minutes, not hours, by distributing the workload across multiple computing nodes in the cloud.

Parametric sweeps

One of Allsolve’s most powerful features for electric motor simulation is its ability to perform variable sweeps in parallel. Engineers often need to simulate motor behavior across a range of operating conditions, for example, different rotor angles.

Instead of running each case one-by-one, Allsolve distributes them across the cloud infrastructure, solving all of them in parallel. This results in substantial time savings.

Case example

Analyzing torque ripple in a PMSM

Simulation objective

The objective of this simulation is to calculate the torque vs mechanical angle plot for a PMSM. This type of analysis provides crucial insight into how the motor generates torque across a full rotation of the rotor.

A key focus is the torque ripple, small oscillations in torque that occur as the rotor turns. Torque ripple can cause unwanted vibration, acoustic noise, and reduce control precision, which is especially problematic in applications like robotics or automotive drivetrains.

Understanding and minimizing torque ripple is therefore a critical part of PMSM design.

The model

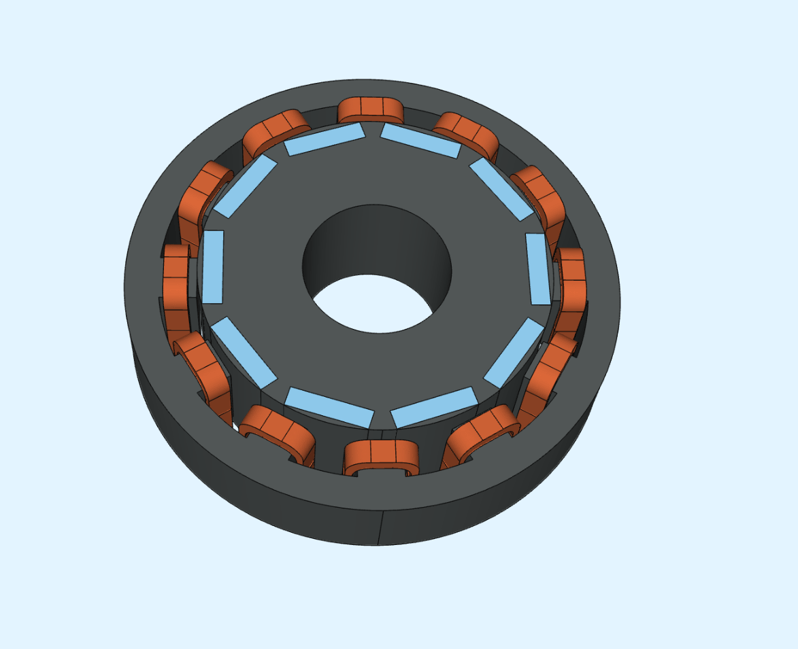

Permanent magnet synchronous motor

Fig. 1: Consists of 12 coils (orange) in the stator and 10 permanent magnets (blue) in the rotor

The simulation captures a 3D electromagnetic model of this motor, accounting for all relevant magnetic fields and material properties. The rotor is rotated in discrete steps to calculate torque at different mechanical angles.

Simulation setup

At each step, the electromagnetic field solution is computed, enabling the post-processing calculation of various motor-related quantities. In this case, the most relevant field solutions are the current density J and the magnetic flux density B. With Quanscient Allsolve’s powerful 3D visualization tools, understanding electromagnetic fields becomes significantly easier and more intuitive.

Fig. 2: Current density J in the stator windings

The visualizations of the electromagnetic field distributions can provide valuable insights into the physical behavior of the system. These field images not only enhance our understanding of key phenomena, such as current flow and magnetic field interaction, but also serve as a useful tool for identifying potential issues in the simulation setup, making them beneficial for both analysis and debugging purposes.

Fig. 3: Magnetic flux density B in the motor

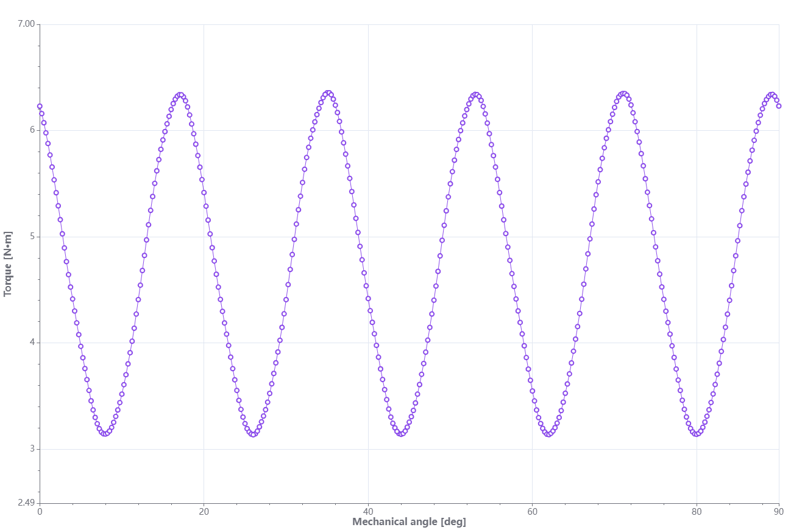

To evaluate torque behavior, the motor was simulated at different rotor positions. Specifically, the rotor was rotated across a 90° segment, with torque calculated at each position.

Fig. 4: Simulated Torque ripple vs Mechanical angle during 90 degrees of rotation

Each point in the final plot corresponds to one fully resolved electromagnetic simulation. Running all these simulations sequentially would take considerable time, even on a high-performance workstation.

With Quanscient Allsolve, all simulations are run in parallel in the cloud. This allows the entire set of results to be generated in a fraction of the time.

The simulation produced a torque vs mechanical angle plot that clearly illustrates torque ripple. The results show the variation in torque as the rotor moves through each of its positions.

This kind of visualization helps engineers understand how geometry, material properties, and winding configuration influence torque production. Based on the results, engineers can adjust design parameters to reduce ripple and improve overall motor smoothness.

Key benefits

High-fidelity modeling

By supporting complex geometries and large models, Quanscient Allsolve makes it possible to simulate detailed motor designs with high accuracy. This ensures that results reflect real-world behavior more closely.

Parametric sweeps

Instead of solving each rotor angle simulation sequentially, Quanscient Allsolve computes them all simultaneously. For a sweep with dozens of angles, this translates to orders-of-magnitude time savings.

In traditional workflows, engineers may be forced to reduce the number of simulations due to time constraints. With Allsolve, full sweeps become practical, enabling more thorough design validation.

Cloud access from any device

Quanscient Allsolve doesn’t require expensive local hardware. Engineers can run these simulations from lightweight laptops, knowing that all heavy lifting happens in the cloud. This makes high-performance simulation more accessible and democratized.

Streamlined workflow from CAD to simulation

The direct CAD file import removes one of the biggest friction points in simulation. Engineers can focus on analysis and design decisions rather than manual geometry preparation.

Conclusion

PMSMs are critical components in modern electric systems. As applications continue to grow in complexity and performance demands rise, simulation is becoming a vital part of motor development.

However, traditional simulation workflows often come with trade-offs. High-fidelity models mean longer computation times, while limited compute resources restrict design iteration. Quanscient Allsolve addresses these challenges by combining cloud-native computing, parallelization, and streamlined workflows in one unified platform.

The case of torque ripple analysis in a PMSM demonstrates this value clearly. By enabling parallel simulations across multiple rotor positions, Allsolve not only saves time but also empowers engineers to explore and optimize more design variations. This leads to better-performing motors, faster development cycles, and more reliable products.

With Allsolve, engineers no longer have to choose between speed and accuracy, or between iteration and deadlines. Simulation becomes a tool for innovation, not a bottleneck.

Whether they’re designing for mobility, automation, or industrial performance, Allsolve offers a modern simulation solution for the challenges of tomorrow’s electric motors.

Join 1000+ others and start receiving our weekly blog posts to your inbox now