MEMS speaker yield optimization

Optimizing MEMS microspeaker yield & audio quality via MultiphysicsAI

Electrostatics • Solid mechanics • Laminar flow • Acoustic waves • Fluid-Structure Interaction • Mesh deformation

The challenge

Silicon-based MEMS speakers face a difficult trade-off: driving them harder increases volume (SPL) but introduces Harmonic Distortion (THD) due to nonlinear electrostatic effects.

Furthermore, microscopic manufacturing variations (tolerances of ±10%) can ruin performance. Traditional simulation is too slow to map these thousands of failure scenarios.

Approach with Quanscient Allsolve

The team performed a Nonlinear Harmonic Balance analysis on the cloud, generating 12,500 simulations in just 20 minutes.

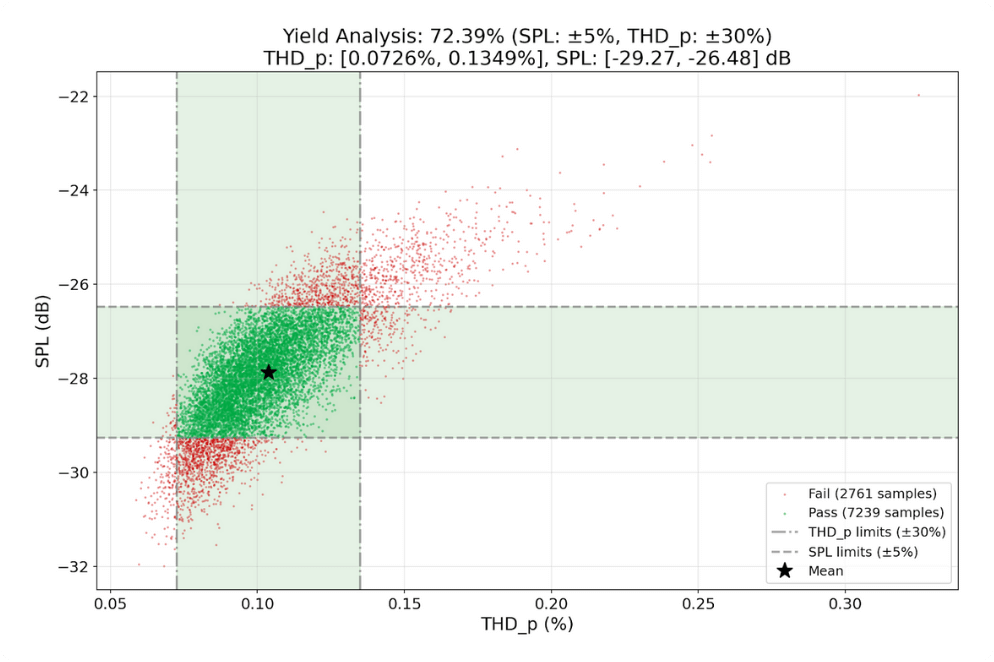

This data trained an AI Surrogate Model which performed a Monte Carlo analysis, predicting how manufacturing tolerances would affect the final production yield.

Key results

- Performance boost: Identified a Pareto-optimal design with ~30% higher SPL while keeping THD below 0.15% (far exceeding the 1% target).

- Yield prediction: The AI predicted a 72% manufacturing yield given ±10% geometric variations, allowing engineers to adjust tolerances before cutting silicon.

- Speed: The AI Surrogate provides instant uncertainty quantification, replacing weeks of prototype testing.