Key takeaways

-

FBARs (Film Bulk Acoustic Resonators) are key components in RF filters for 5G and 6G wireless systems.

-

Their performance depends on coupled piezoelectric, mechanical, and electrostatic behavior.

-

Quanscient Allsolve enables fully coupled, 3D multiphysics simulations, crucial for identifying unwanted lateral modes and optimizing performance.

-

Integration with SoftMEMS and Siemens L-Edit allows automated 3D model generation from process design kits (PDKs), fabrication process descriptions and mask layouts, ensuring manufacturable, automated, and scalable workflows.

-

Case results show clear identification of series and parallel resonances, detection of spurious lateral modes, and their mitigation through geometry optimization.

Introduction

Film Bulk Acoustic Resonators (FBARs) are high-frequency piezoelectric devices used in RF filtering applications. They serve as essential components in wireless communication systems, including 5G and upcoming 6G technologies. In these systems, RF filters separate transmit and receive bands, ensuring high selectivity, signal integrity, and efficient power transfer.

An FBAR essentially functions as a parallel-plate capacitor where the dielectric is replaced by a piezoelectric material such as aluminum nitride (AlN). When a voltage is applied across the electrodes, the piezoelectric film deforms mechanically, creating acoustic waves within the structure. The device resonates when the acoustic wavelength equals twice the film thickness, this defines the fundamental resonance frequency.

Achieving high-quality performance in FBARs requires addressing several challenges:

-

Ensuring high quality factors (Q) and sharp resonance peaks.

-

Attaining high selectivity between transmit and receive bands.

-

Suppressing undesired lateral modes, which introduce spurious resonances and degrade filter response.

Traditional simulation approaches often separate electrostatic and mechanical analyses or rely on simplified 2D representations. However, lateral modes and 3D acoustic effects can only be fully captured in 3D, fully coupled electromechanical simulations. This is where Quanscient Allsolve provides a significant advantage.

What is the added value with Quanscient Allsolve?

Quanscient Allsolve is a cloud-based multiphysics simulation platform that enables fully coupled multiphysics, including structural mechanics, electrostatics, and piezoelectricity, in a single, consistent solution.

For FBAR devices, Allsolve provides:

-

Fully coupled electromechanical and piezoelectric analysis.

-

Efficient 3D harmonic simulations at GHz frequencies.

-

Automated workflows that connect design tools to simulation.

-

High scalability across CPUs, enabling millions of degrees of freedom (DoFs) to be solved efficiently.

By solving all physics simultaneously rather than iteratively, Allsolve ensures accurate representation of coupled fields. This capability is crucial in devices like FBARs, where small variations in electric field, film thickness, or substrate geometry can significantly affect resonance frequency and mode behavior.

Quanscient Allsolve’s cloud-based parallel solver also allows multiple parametric models to be analyzed in parallel. Engineers can sweep parameters, run optimization loops, and perform Monte Carlo analysis efficiently, tasks that would otherwise require substantial computational infrastructure.

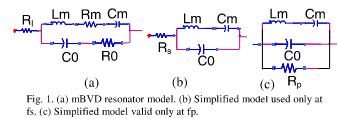

Ref: Feld, et al. DOI 10.1109/ULTSYM.2008.0105

-png.png?width=781&height=551&name=Insertion%20Loss%20(dB)-png.png)

Source: https://docs.broadcom.com/doc/AV02-1743EN

Case example

Film Bulk Acoustic Resonator (FBAR)

Simulation objective

The goal was to perform a fully coupled electromechanical analysis of an FBAR device to:

-

Evaluate series and parallel resonances.

-

Identify and characterize undesired lateral modes.

-

Demonstrate how design modifications mitigate these effects.

-

Showcase workflow automation and computational performance of Allsolve.

The model

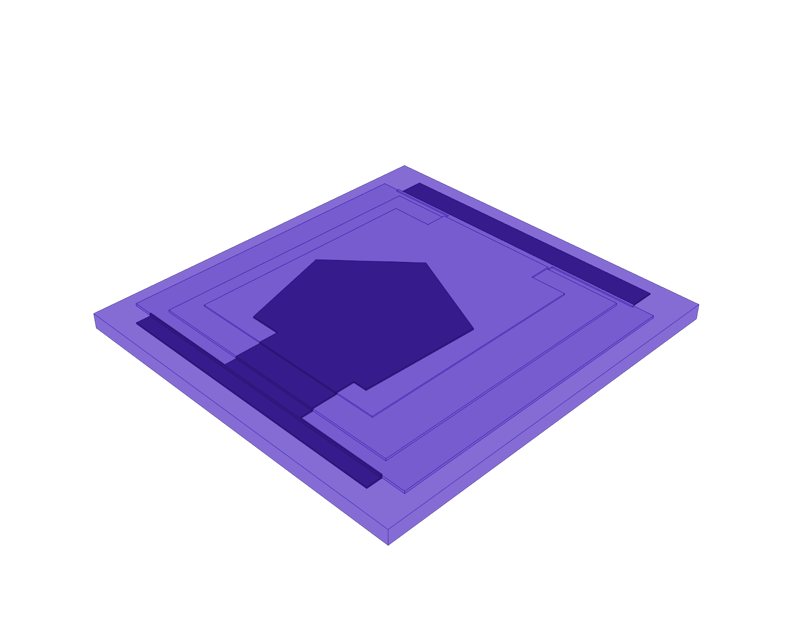

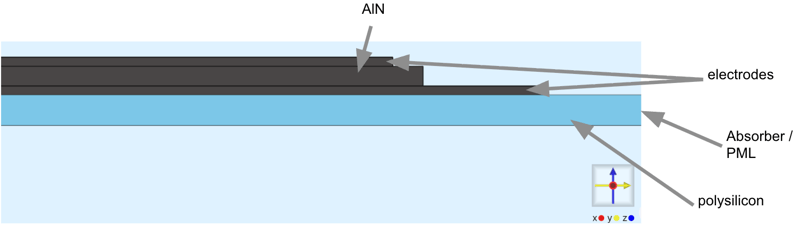

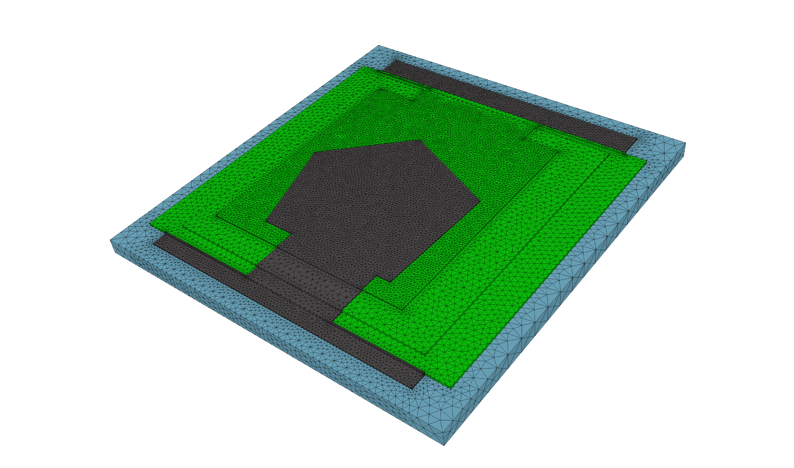

A 3D coupled electromechanical model was constructed with the following parameters:

| Parameter | Material / Value |

|---|---|

| Piezoelectric layer | AlN (Aluminum Nitride), 650 nm |

| Top/Bottom electrodes | Molybdenum, 300 nm |

| Substrate | Polysilicon, 1 µm |

| Active area | 125 × 78.4 µm |

|

Nominal series resonance frequency |

2.677 GHz |

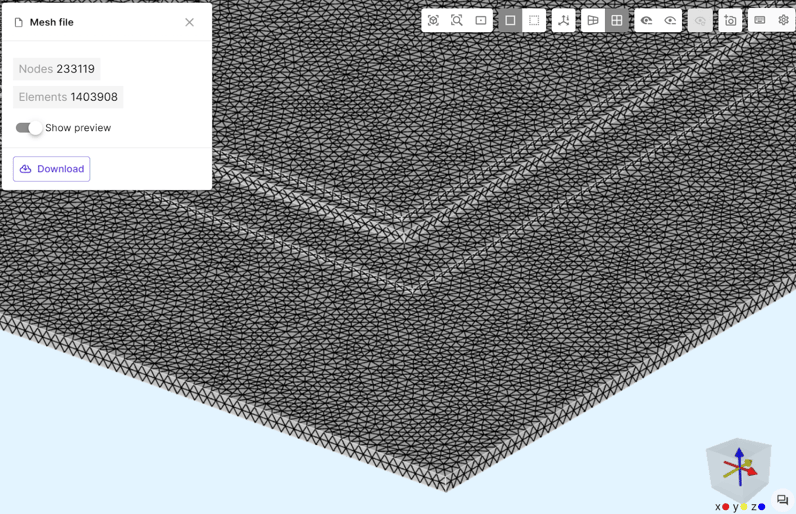

Boundary conditions were set to absorbing on the substrate sides to prevent wave reflections, mimicking an open environment. An unstructured second-order tetrahedral mesh was used, with fine resolution to capture GHz-range vibrations.

The model consisted of approximately 10.1 million degrees of freedom (DoFs) and was solved using 30 CPUs, taking roughly 315 seconds per frequency point (≈2.63 core-hours/frequency). The harmonic sweep covered 401 frequency points near the nominal resonance (2.678 GHz).

We use a simplified square FBAR geometry to illustrate the physics and show what can be done with Quanscient Allsolve. More realistic device geometries are introduced later in the blog.

Unstructured 2nd order tetrahedra 650nm

Key results

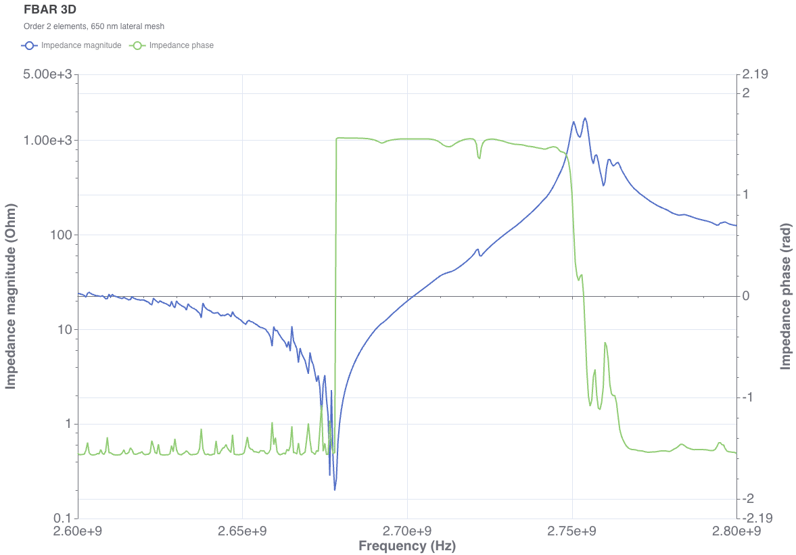

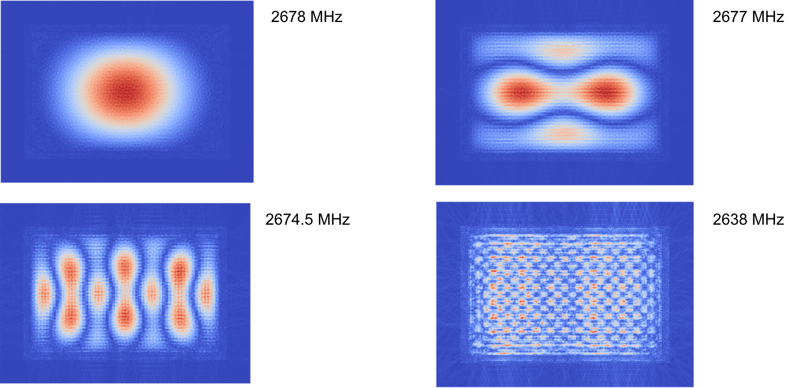

The impedance response showed clear series and parallel resonance peaks:

-

Series resonance (fs ≈ 2.677 GHz): low impedance, representing maximum power transfer (device acts as a short).

-

Parallel resonance (fp slightly higher): high impedance, corresponding to minimal current (device behaves as an open).

Between these points lies the passband, where impedance matching enables optimal power transfer.

However, small ripples appeared in the impedance curve, caused by lateral acoustic modes, vibrations propagating horizontally across the piezoelectric film. These lateral modes are undesirable, as they introduce noise and degrade selectivity. Visualization of the mode shapes confirmed that while the primary mode corresponded to the intended thickness vibration, additional spurious modes were excited laterally.

The 3D modeling approach in Allsolve was essential to reveal these lateral effects, which cannot be accurately captured in simplified 2D models.

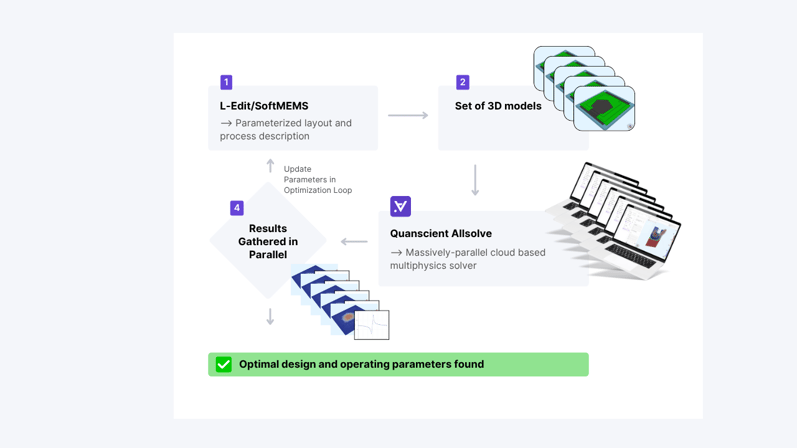

Geometry generation and automation

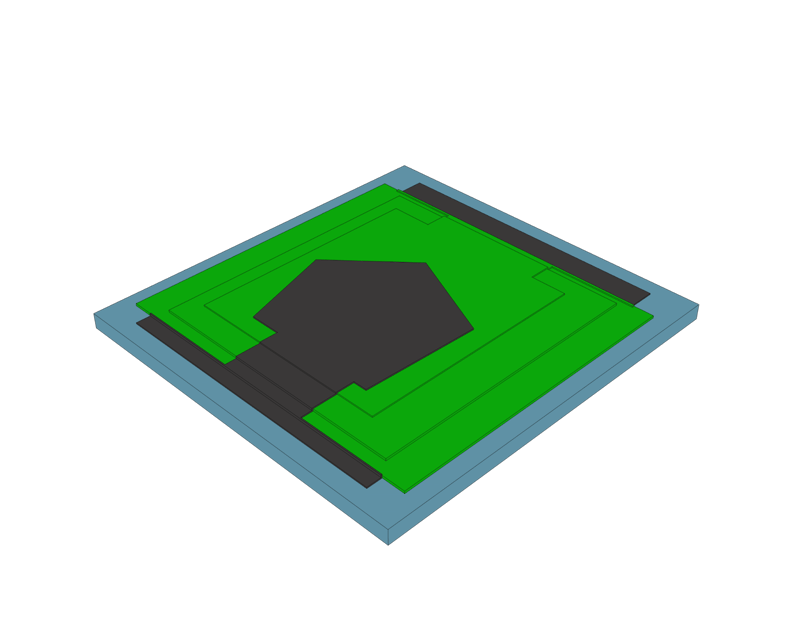

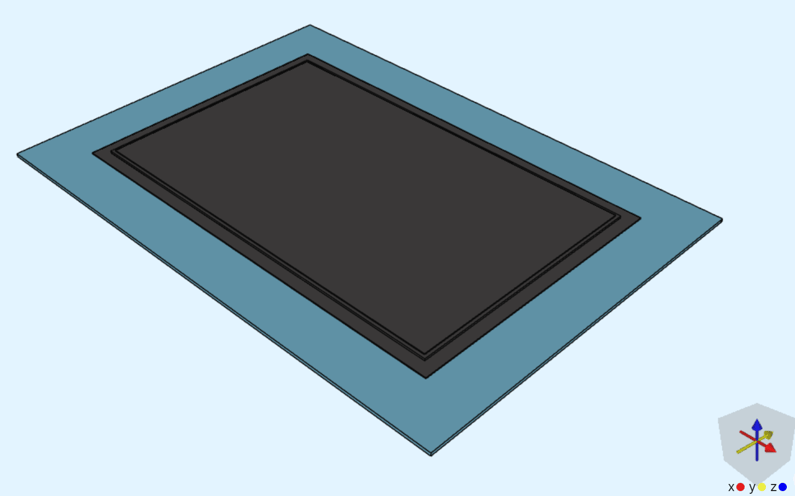

To demonstrate practical design workflows, the team then used SoftMEMS and Siemens L-Edit for geometry generation and parameter management to create realistic geometries.

-

3D geometries were built directly from mask layout and a fabrication process description.

-

Materials and boundary conditions were automatically assigned from geometry definitions.

-

The entire toolchain, from geometry definition to simulation setup, was automated using Python scripting and the Quanscient SDK.

-

This enabled Design of Experiments (DoE), optimization loops, and Monte Carlo analyses with minimal manual intervention.

The integration workflow is summarized as:

-

Define and create multiple 3D geometries in L-Edit/SoftMEMS.

-

Export to Allsolve using the API.

-

Run automated simulations and collect results.

-

Update parameters iteratively to refine performance.

This automation drastically reduces setup time and eliminates manual errors that typically arise during model translation. Moreover, it supports large-scale studies where hundreds or thousands of design variants can be simulated efficiently in parallel on the cloud.

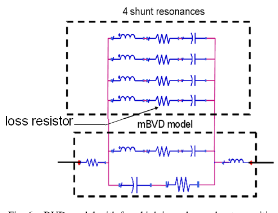

Lateral mode mitigation and optimization

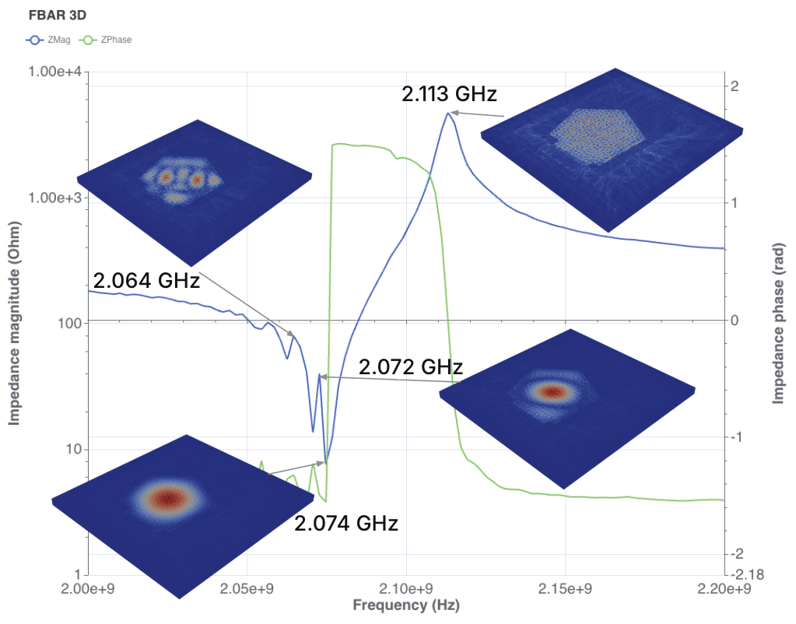

To further investigate mitigation strategies, the team performed additional 3D harmonic simulations with modified geometries.

These runs used smaller models (approximately 2.4 million DoFs) and 10 CPUs, achieving about 102 seconds per frequency point (~0.32 core-hours/frequency).

The updated design produced a series resonance at 2.074 GHz and a parallel resonance slightly above 2.113 GHz.

The impedance spectrum confirmed that adjusting the device shape reduced lateral mode activity, resulting in a smoother response and improved selectivity. The lateral ripples observed in the baseline design were largely suppressed.

These results validated that lateral modes can be effectively mitigated by geometry optimization—modifying electrode shape, applying apodization, or refining anchoring configurations. Allsolve’s ability to perform fully coupled 3D analyses was critical for capturing these subtle effects.

Key benefits demonstrated

- Fully coupled multiphysics simulation

Structural, electrostatic, and piezoelectric interactions were solved simultaneously, ensuring self-consistent results. -

3D modeling accuracy

Only a 3D harmonic analysis can capture lateral modes; Allsolve’s solver efficiently handles multi-million-DoF models at GHz frequencies. -

Automation and integration

SoftMEMS and L-Edit integration streamlined geometry creation and setup. The Python-based SDK supported parametric and statistical analyses. -

Scalable cloud computation

Simulations were distributed across multiple CPUs in the cloud, minimizing time per frequency sweep and enabling parallelized parametric studies. -

Practical insight for optimization

Identifying and mitigating lateral modes directly translated into performance improvements—better frequency response, reduced ripple, and higher selectivity. -

Manufacturable design fidelity

Parameterized workflows using PDK-based geometry ensured that simulations aligned with real fabrication constraints.

Other benefits of Quanscient Allsolve

Beyond FBARs, Allsolve’s multiphysics framework applies broadly to MEMS and RF devices that couple electrical and mechanical fields.

For example, CMUTs (Capacitive Micromachined Ultrasonic Transducers) also combine structural mechanics and electrostatics, and Allsolve can simulate their behavior using the same coupled approach. These devices benefit from identical capabilities,piezoelectric or electrostatic actuation, GHz-range response, and full 3D modeling.

Allsolve’s high-performance architecture supports:

-

Massively parallel computation for faster convergence.

-

Parametric and statistical automation for design optimization.

-

Consistent multiphysics coupling across domains without manual linking or external solvers.

-

Scalable licensing and cloud execution, allowing organizations to run large simulation campaigns without infrastructure bottlenecks.

Such flexibility makes Allsolve a valuable platform for both research and production-level engineering across MEMS, RF, and sensor applications.

Quanscient Allsolve

Powerful multiphysics simulation platform

Run fast, accurate, and scalable cloud-based simulations with Quanscient Allsolve

Key features of Quanscient Allsolve for product design simulations →

Conclusion

This FBAR case study demonstrates how Quanscient Allsolve enables realistic, fully coupled multiphysics simulation for high-frequency piezoelectric devices.

Starting from a basic structure and progressing to an automated, manufacturable design imported from SoftMEMS, the workflow illustrates how lateral modes can be identified and mitigated using geometry optimization.

The results show:

-

Accurate impedance prediction and mode identification.

-

Detection of undesired lateral resonances.

-

Improvement in filter response through design iteration.

-

Efficient, scalable simulation through automation and cloud computing.

For engineers working on RF filter technologies and MEMS devices, these capabilities translate directly into shorter development cycles, fewer fabrication iterations, and higher-performing designs.

Ultimately, Allsolve’s unified multiphysics environment, combining structural, electrostatic, and piezoelectric physics, offers the precision and scalability needed for next-generation RF component development.

By bridging the gap between design, simulation, and fabrication, it provides a path toward reliable, optimized, and manufacturable high-frequency resonators.

Learn more and get in touch now at quanscient.com